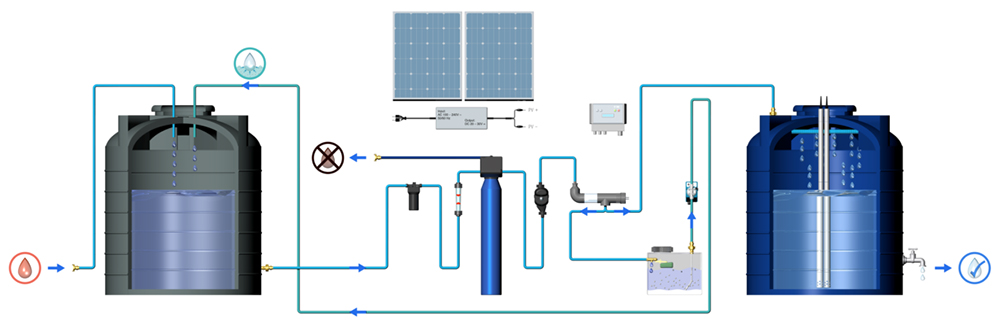

AUTARCON developed a new electro-chlorination unit, which is specifically adapted to the local conditions found in the Indian pilot sites. The station doses chlorine in very small quantities into the water for residual disinfection. This disinfectant is produced directly at site by converting available sodium chloride to hypochlorite by means of electrolysis. Through an internal sensor the amount of chlorine needed to achieve the treatment target is continuously adapted to the actual demand. Compared to common chlorination systems this substantially reduces the amount of disinfectant, reducing costs, and the risk of potentially formed by-products. The station will supply up to 30 m³ of pathogen free water per day meeting Indian and international guidelines.

Natural pre-treatment through River Bank Filtration

If surface water is used as source water and if local conditions permit, the drinking water treatment process will be supported by Bank Filtration. This natural treatment step will remove most of the relevant contaminants from the source water and facilitates reliable and robust treatment conditions. In combination with an advanced media filtration module, this will substitute more technical approaches such as the ultra-filtration (UF) and further increases the robustness of the here chosen approach.

Filtration of contaminants

If contaminated groundwater is used as source water, the station will be equipped with additional filtration modules to remove ammonium, iron, manganese and arsenic. The treatment steps are based on catalytic and oxidative reactions. Compared to adsorptive media no exchange of such will be required here.

The complete treatment process including pumping, filtering, disinfectant production, dosing and water quality monitoring will be powered by solar-PV generated electricity - even during monsoon period.

The treatment system will be equipped with an online SCADA and remote control system. Through this all operational data will be online accessible simplifying water quality monitoring and troubleshooting in remote developing regions substantially and saving costs. The stations will be able to control their system status autonomously and indicate potential issues already before they occur. This gives the operator time to plan maintenance steps before the fails, reducing downtimes substantially. To some extend the operator will be able to remotely control and adjust the treatment process.